Calcium oxide (CaO), commonly known as quicklime or burnt lime, is a chemical compound with widespread industrial significance. It is one of the oldest known chemical substances, used by ancient civilizations for construction and metallurgy. Today, calcium oxide plays a pivotal role in various industries, from manufacturing and environmental applications to agriculture and construction. The compound’s reactivity with water and its ability to neutralize acidity make it highly versatile and valuable in many sectors.

This article will provide a detailed overview of calcium oxide, including its chemical properties, production processes, reactions, and real-world applications. Examples will be used to explain its diverse uses and its importance in modern industry.

What Is Calcium Oxide?

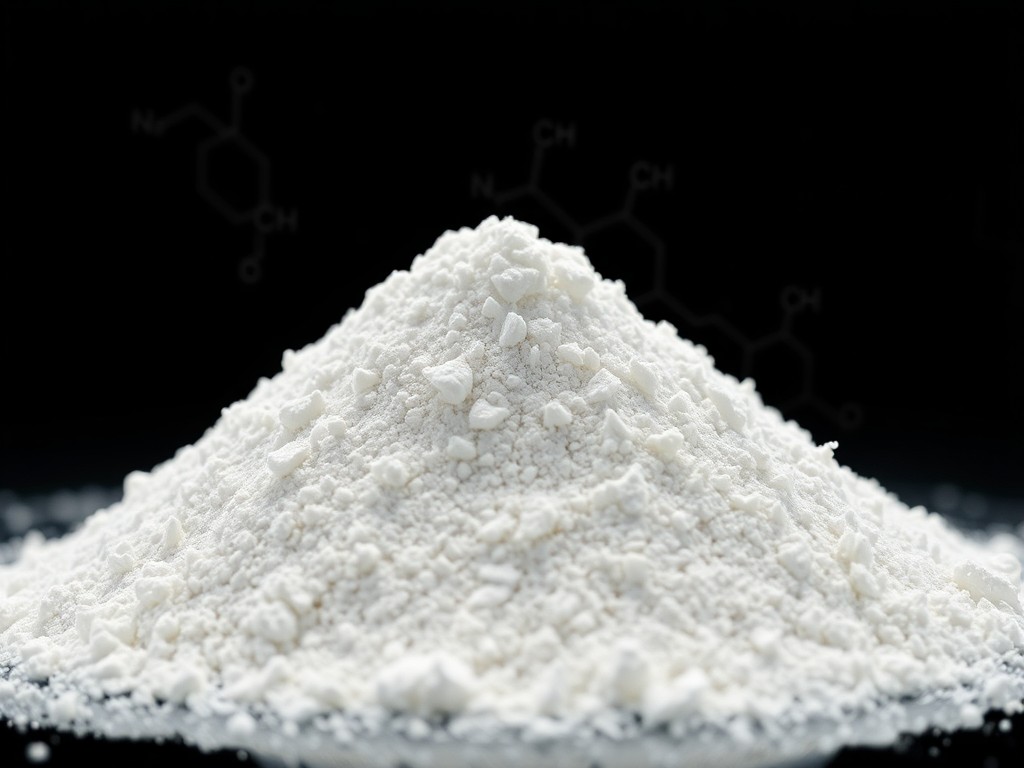

Calcium oxide is a white, crystalline, or powdery compound, typically derived from limestone (calcium carbonate, CaCO₃). When limestone is heated to high temperatures (around 900–1000°C), it undergoes a process called calcination, during which it decomposes into calcium oxide and carbon dioxide (CO2). The chemical reaction for this process is:

CaCO3 (s)→CaO (s)+CO2 (g)

Calcium oxide is classified as an alkaline substance because it reacts readily with water to form calcium hydroxide (Ca(OH)2), a strong base. This reactivity makes it useful in a variety of chemical processes where it acts as a neutralizer, desiccant, or catalyst.

Physical Properties of Calcium Oxide:

- Appearance: White or grayish-white solid or powder.

- Density: Approximately 3.34 g/cm³.

- Melting Point: Around 2572°C.

- Boiling Point: 2850°C.

- Solubility: Slightly soluble in water, highly reactive with water (forms calcium hydroxide).

Calcium oxide is thermally stable and does not decompose under typical environmental conditions. Its basicity and reactivity with acids are important for its many uses, especially in environmental and industrial contexts.

Production of Calcium Oxide

The primary source of calcium oxide is limestone, a sedimentary rock composed mainly of calcium carbonate. The production of calcium oxide is a straightforward thermal decomposition process known as calcination. The steps involved in producing calcium oxide are as follows:

1. Mining and Preparation of Limestone

The process begins with the extraction of limestone from quarries or mines. The limestone is then crushed into smaller pieces to increase the surface area for more efficient heating.

2. Calcination Process

Once the limestone is prepared, it is heated in a lime kiln at high temperatures, typically around 900 to 1000°C. This temperature is high enough to decompose the calcium carbonate into calcium oxide and carbon dioxide gas, which is released into the atmosphere.

The chemical reaction for this process is:

![]()

The lime kiln can be of different types, such as rotary kilns or shaft kilns, but the underlying process remains the same: heating the limestone to a temperature that facilitates the breakdown of calcium carbonate.

3. Collection of Calcium Oxide

After the calcination process, the calcium oxide is collected as a solid, typically in powder form. It can be further processed or stored, depending on its intended use. Calcium oxide is often slaked with water to form calcium hydroxide for certain applications, while in other cases, it is used directly as quicklime.

Chemical Reactions of Calcium Oxide

Calcium oxide is highly reactive, especially with water and acids. Its reactivity underpins its numerous industrial applications. Below are some of the key chemical reactions involving calcium oxide:

1. Reaction with Water: Formation of Calcium Hydroxide

One of the most notable reactions of calcium oxide is with water, where it forms calcium hydroxide, also known as slaked lime. This exothermic reaction releases a significant amount of heat, and the resulting solution is a strong base.

The reaction is:

CaO (s)+H2O (l)→Ca(OH)2 (aq)+Heat

This reaction is used in several applications, particularly in the preparation of mortar for construction and the neutralization of acidic substances.

2. Reaction with Carbon Dioxide: Formation of Calcium Carbonate

When calcium oxide reacts with carbon dioxide, it reforms calcium carbonate. This reaction is important in the context of lime cycling, where quicklime can be converted back to limestone.

The reaction is:

CaO (s)+CO2 (g)→CaCO3 (s)

This process is utilized in some industrial applications for carbon sequestration or the production of cement.

3. Reaction with Acids

Calcium oxide reacts readily with acids to form calcium salts and water. This makes it an effective neutralizing agent in chemical processes that require the removal of acidic impurities.

For example, the reaction with hydrochloric acid is:

CaO(s)+2HCl(aq)→CaCl2(aq)+H2O(l)

This reaction is used in processes where acidic byproducts need to be neutralized, such as in waste treatment or chemical manufacturing.

Applications of Calcium Oxide

Calcium oxide has a wide array of applications across various industries due to its reactivity and alkaline nature. Below are some of the key applications:

1. Construction Industry

One of the oldest and most common uses of calcium oxide is in the construction industry, where it is used in the production of cement and mortar. When calcium oxide is slaked with water, it forms calcium hydroxide, which reacts with carbon dioxide in the air to form calcium carbonate. This process helps bind building materials together, forming a hard, durable structure.

In cement production, calcium oxide acts as a major component of the clinker, which is ground to form Portland cement. The addition of calcium oxide in mortar helps improve its plasticity and workability during construction.

Example: Lime mortar, made from calcium oxide, was widely used in ancient Roman and Greek architecture. Many historic buildings still stand today due to the durable properties of lime-based construction materials.

2. Environmental Applications

Calcium oxide is commonly used for environmental remediation and pollution control due to its ability to neutralize acidic pollutants. Its alkaline nature allows it to treat a variety of environmental issues:

- Flue Gas Desulfurization (FGD): In coal-fired power plants, calcium oxide is used to remove sulfur dioxide (SO2) from exhaust gases. The calcium oxide reacts with sulfur dioxide to form calcium sulfite (CaSO3), which can then be processed or discarded, reducing the emission of harmful gases into the atmosphere.CaO (s)+SO2 (g)→CaSO3 (s)

- Water Treatment: Calcium oxide is used in water treatment plants to adjust pH levels and remove impurities, such as heavy metals and phosphates, from drinking water. It can also precipitate unwanted compounds in industrial wastewater, making it easier to filter and purify.

3. Steel Industry

In the steel industry, calcium oxide is a critical fluxing agent used in the production of steel. It is added to the blast furnace to remove impurities such as silica, sulfur, and phosphorus from iron ore. The calcium oxide combines with these impurities to form slag, which is removed, leaving behind purified iron.

The chemical reaction between calcium oxide and silica (SiO2\text{SiO}_2) forms calcium silicate, which is a component of the slag:

CaO (s)+SiO2 (s)→CaSiO3 (l)

By removing these impurities, calcium oxide ensures the production of high-quality steel.

4. Agriculture

In agriculture, calcium oxide is used to improve soil quality by increasing the pH of acidic soils. This process, known as liming, helps neutralize acidity in the soil, improving the availability of essential nutrients like nitrogen, phosphorus, and potassium. Liming is particularly important in regions with acidic soils, where crop yields would otherwise be reduced due to nutrient deficiencies.

In addition to improving soil pH, calcium oxide is also used to treat animal waste in farms, reducing odors and preventing the spread of harmful pathogens by controlling pH levels.

Example: Farmers often spread lime (calcium oxide) on fields before planting crops to ensure that the soil pH is balanced. This improves crop growth and increases yields by providing a more favorable environment for plant roots.

5. Chemical Manufacturing

Calcium oxide is widely used in various chemical processes as a reagent. For example, in the production of sodium carbonate (soda ash), calcium oxide is used to regenerate ammonia from ammonium chloride in the Solvay process. This role is crucial in producing soda ash, which is a key ingredient in glass manufacturing and many other industrial processes.

Additionally, calcium oxide is used in the production of calcium carbide, which is an important intermediate in the chemical synthesis of acetylene.

6. Food Industry

In the food industry, calcium oxide is used in several applications. It is used in the production of pickles and tortillas, where it acts as a firming agent or pH regulator. In sugar refining, calcium oxide is added to raw sugar juice to precipitate impurities and clarify the solution.

Health and Safety Considerations

While calcium oxide has numerous beneficial uses, it is also a hazardous substance when handled improperly. Because calcium oxide is highly reactive with water, it can cause severe burns when it comes into contact with skin or eyes. Inhalation of calcium oxide dust can irritate the respiratory system, leading to coughing or difficulty breathing.

In industrial settings, proper personal protective equipment (PPE) is essential when working with calcium oxide. Workers should wear gloves, safety goggles, and dust masks to prevent accidental exposure. Additionally, calcium oxide should be stored in airtight containers to prevent it from reacting with moisture in the air.

Conclusion

Calcium oxide is a versatile compound that plays a vital role in a wide range of industries, from construction and steel production to environmental remediation and agriculture. Its ability to react with water, acids, and gases makes it a valuable reagent in many chemical processes, while its basic properties allow it to neutralize acidity and improve the quality of materials and environments.

Through its applications in cement production, water treatment, flue gas desulfurization, and soil conditioning, calcium oxide continues to be an essential industrial material. Despite its potential hazards, when used with proper safety measures, calcium oxide proves to be an invaluable tool for modern industry and technology.