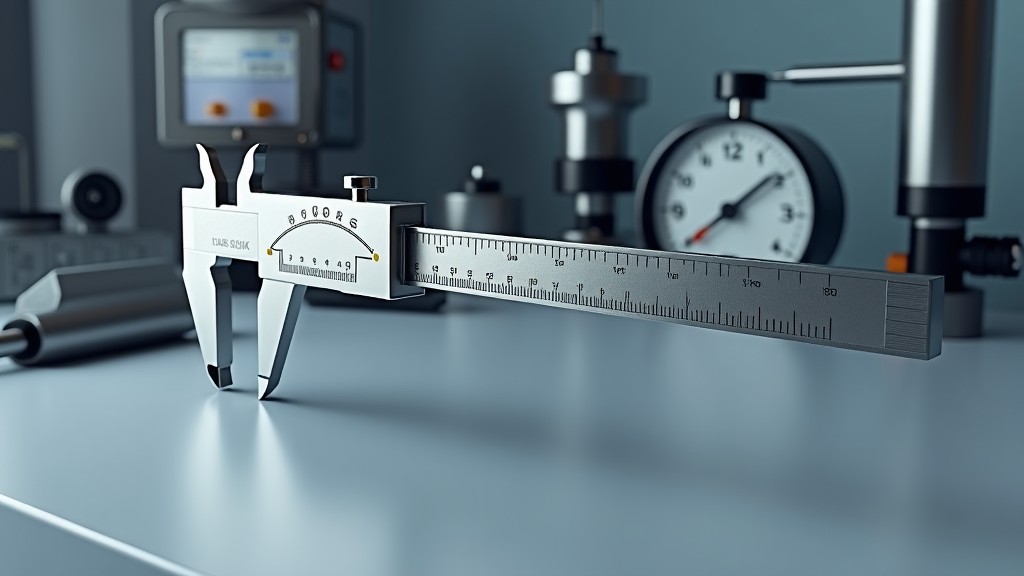

The Vernier caliper is a precision instrument used to measure dimensions with high accuracy. Invented by Pierre Vernier in 1631, the Vernier caliper allows users to measure internal, external, and depth dimensions of objects, providing readings with a precision that typical rulers or tape measures cannot achieve. It is an essential tool in fields like engineering, manufacturing, physics, and quality control, where precise measurements are crucial.

This article explores the Vernier caliper, its parts, how to use it, reading techniques, and practical examples of its applications.

Parts of a Vernier Caliper

A typical Vernier caliper has the following parts:

- Main Scale: The fixed scale marked on the body of the caliper, usually graduated in centimeters (cm) or inches.

- Vernier Scale: The movable scale that slides along the main scale, providing an additional level of precision.

- Fixed Jaw: The stationary jaw that serves as one point of contact for the measurement.

- Sliding Jaw: The movable jaw that can be adjusted along the main scale to grip the object being measured.

- Depth Rod: A thin, extendable rod at the end of the caliper for measuring the depth of holes or recesses.

- Thumb Screw: Used to lock the sliding jaw in place, ensuring stable readings.

- Fine Adjustment Screw: Found on more advanced Vernier calipers, allowing for precise adjustments of the sliding jaw.

Measurement Types with a Vernier Caliper

The Vernier caliper allows for three main types of measurements:

- External Measurement: Used to measure the outer diameter or width of an object, such as the thickness of a pipe or the width of a block.

- Internal Measurement: Used to measure the inner diameter or width of an object, such as the diameter of a hole or the gap between two surfaces.

- Depth Measurement: Used to measure the depth of a cavity or hole.

Each of these measurement types is performed using different parts of the Vernier caliper. The external jaws are used for outer measurements, the internal jaws for inner measurements, and the depth rod for depth measurements.

How to Use a Vernier Caliper

Using a Vernier caliper requires proper alignment and reading techniques to ensure accuracy. Let’s go through the basic steps:

- Positioning the Object: Place the object between the jaws (external measurement), insert the internal jaws into a cavity (internal measurement), or position the depth rod in a hole (depth measurement).

- Adjusting the Jaws: Carefully slide the movable jaw until it gently touches the object. For a depth measurement, extend the depth rod until it reaches the bottom.

- Lock the Measurement: Use the thumb screw to lock the sliding jaw in place, ensuring that the measurement remains stable.

- Reading the Scale: Read the main scale and then the Vernier scale to obtain the final measurement. The main scale provides the integer part, and the Vernier scale gives the decimal precision.

Reading a Vernier Caliper

Reading a Vernier caliper is straightforward once you understand how to interpret the scales. Let’s break down the process.

- Main Scale Reading: Start by reading the main scale, which shows the measurement in millimeters or inches. The main scale reading is taken at the zero mark of the Vernier scale.

- Vernier Scale Reading: The Vernier scale provides an additional measurement by indicating the decimal fraction of the main scale’s smallest division. Find the mark on the Vernier scale that aligns perfectly with a mark on the main scale.

The final measurement is the sum of the main scale reading and the Vernier scale reading.

Example of Reading a Vernier Caliper

Suppose you are using a Vernier caliper with metric units. The main scale shows a reading of 10 mm, and the 0.7 mm mark on the Vernier scale aligns with a mark on the main scale.

- Main Scale Reading: 10 mm

- Vernier Scale Reading: 0.7 mm

Total Measurement:

![]()

This combined reading gives a precise measurement of 10.7 mm.

Understanding Vernier Scale Precision

The precision of a Vernier caliper depends on the smallest reading on its Vernier scale, called the least count. For example, if the least count is 0.02 mm, the caliper can measure dimensions as accurately as 0.02 mm. The least count is calculated by dividing the smallest division on the main scale by the number of divisions on the Vernier scale.

Formula for Least Count

![]()

For instance, if the main scale’s smallest division is 1 mm and the Vernier scale has 50 divisions, the least count is:

![]()

Advantages of Using a Vernier Caliper

- High Precision: Vernier calipers provide precise measurements with fine increments, often up to 0.02 mm or 0.001 inches.

- Versatility: They can measure external, internal, and depth dimensions, making them suitable for various applications.

- Ease of Use: With practice, Vernier calipers are easy to use, providing reliable measurements in a short time.

- Portable and Durable: Most Vernier calipers are compact and made of durable materials, making them easy to transport and resistant to wear.

Applications of Vernier Calipers

Vernier calipers are widely used in industries, laboratories, and workshops where precise measurements are essential. Here are some common applications:

- Engineering and Manufacturing: Engineers and machinists use Vernier calipers to check the dimensions of manufactured parts, ensuring that they meet design specifications.

- Metalworking and Machining: In metalworking, Vernier calipers are used to measure the thickness, diameter, and depth of metal components, which is crucial for quality control.

- Scientific Research: Laboratories use Vernier calipers to measure specimens or scientific equipment dimensions accurately, often down to the millimeter.

- Automotive Industry: Mechanics and automotive engineers use Vernier calipers to measure engine parts, bolt diameters, and gaps, ensuring compatibility and safety.

- Jewelry Making: Jewelers use Vernier calipers to measure gemstones, ring diameters, and other small components, where precision is critical for quality and aesthetics.

Example Applications of Vernier Caliper Measurements

Example 1: Measuring the Diameter of a Cylinder

Suppose you need to measure the diameter of a metal rod to ensure it meets design requirements. Place the rod between the external jaws of the Vernier caliper, adjust the jaws until they touch the rod, and lock the position. If the main scale reads 5 mm and the 0.4 mm mark on the Vernier scale aligns, the total diameter is:

![]()

This precise diameter measurement allows quality control inspectors to confirm that the rod matches the required specifications.

Example 2: Measuring the Depth of a Hole

Vernier calipers can also measure the depth of holes, which is essential in many manufacturing processes. For instance, a manufacturer may need to check the depth of a drilled hole to ensure that it can accommodate a specific part. Insert the depth rod into the hole and extend it until it reaches the bottom. If the main scale reads 12 mm and the Vernier scale reads 0.3 mm, the depth of the hole is:

![]()

This level of precision helps ensure that drilled holes meet exact specifications.

Example 3: Measuring Internal Dimensions

To measure the internal diameter of a hollow pipe, use the internal jaws of the Vernier caliper. Insert the jaws into the pipe and adjust them until they contact the inner walls. Suppose the main scale reads 20 mm and the Vernier scale shows an alignment at 0.8 mm. The internal diameter is:

![]()

This allows engineers to verify that components like pipes, rings, and tubes fit together as intended.

Types of Vernier Calipers

There are several types of Vernier calipers, each tailored to specific needs and measurement types:

- Manual Vernier Calipers: These are traditional calipers with a manual sliding Vernier scale. Users must interpret the scale manually, making them ideal for hands-on applications where visual inspection is feasible.

- Digital Vernier Calipers: These calipers have digital displays, making it easy to read measurements without manually aligning the Vernier scale. They are widely used for convenience and accuracy.

- Dial Vernier Calipers: This type of caliper uses a dial with a pointer to show the measurement reading. The pointer rotates around the dial as the jaws move, offering an alternative to the Vernier scale.

- Depth Vernier Calipers: Specifically designed for measuring the depth of cavities and holes, these calipers feature an extended depth rod for precise depth measurements.

Each type of Vernier caliper has distinct advantages. For instance, digital calipers provide quick, easy readings, while traditional manual Vernier calipers are durable, accurate, and do not require batteries.

Limitations of Vernier Calipers

While Vernier calipers are valuable tools, they have some limitations:

- Measurement Range: Vernier calipers typically measure within a limited range (e.g., up to 150 mm or 300 mm), making them unsuitable for very large measurements.

- Temperature Sensitivity: Changes in temperature can affect the accuracy of metal Vernier calipers, as thermal expansion may alter readings.

- Skill Requirement: Manual reading of a Vernier scale requires some skill, and incorrect alignment or misinterpretation can lead to errors.

- Not Ideal for Soft Materials: Calipers can dent or deform soft materials, such as rubber or plastic, leading to inaccurate measurements.

Conclusion

The Vernier caliper is an indispensable precision measurement tool used across numerous industries. With its capability to measure external, internal, and depth dimensions with high accuracy, it has become essential in fields like engineering, machining, and quality control. Understanding how to read and use a Vernier caliper effectively is a valuable skill, allowing users to obtain precise measurements crucial for product quality, scientific research, and engineering applications. While it has some limitations, the Vernier caliper remains a reliable tool, exemplifying the importance of precision and attention to detail in measurement.